Vegetable Tomato Sesame Seed Grading and Sorter Separator Machine

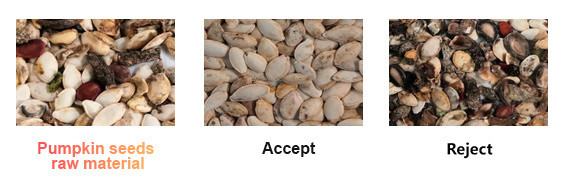

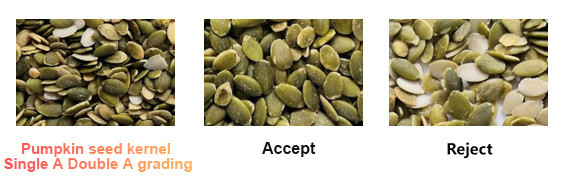

In the agricultural sector, seeds like coffee beans, maize, beans, rice, and various other grains are sorted using Techik Vegetable Tomato Sesame Seed Grading and Sorter Separator Machines. In the case of food processing, seeds like sunflower seeds, pumpkin seeds, and sesame seeds are also sorted by color to ensure uniformity in quality and remove any discolored, damaged, or foreign material.

Color sorting technology allows for high-speed and accurate separation of seeds, enhancing the overall quality of the final product by removing defective or unwanted items from the batch.

The sorting performance of Techik Vegetable Tomato Sesame Seed Grading and Sorter Separator Machines:

Techik Vegetable Tomato Sesame Seed Grading and Sorter Separator Machines find applications across various industries involved in seed production, agriculture, and food processing. Some key applications include:

Agricultural Seed Sorting: Seed color sorters are extensively used in the agricultural sector to sort a wide range of seeds such as maize, wheat, rice, soybeans, sunflower seeds, coffee beans, and more. They help in segregating seeds based on color, size, shape, and defects, ensuring the production of high-quality seeds for planting.

Quality Control in Seed Production: Seed companies use color sorters to ensure the quality of seeds before packaging and distribution. By removing defective, discolored, or damaged seeds, these machines enhance the overall quality of the seed batch.

Removal of Impurities: In addition to sorting seeds based on color, these machines can identify and eliminate impurities such as stones, debris, or other foreign materials mixed with the seeds, ensuring purity and cleanliness.

Food Processing Industry: Seed color sorters are employed in the food processing industry for sorting various edible seeds like sesame seeds, pumpkin seeds, lentils, chickpeas, and others. They ensure uniformity in color and quality, meeting consumer preferences and industry standards.

Enhanced Crop Yield: By eliminating low-quality seeds or contaminants, color sorters contribute to improved crop yield. Planting high-quality seeds sorted by color and other characteristics can result in better germination rates and healthier plants.

Export and Import Regulations Compliance: Sorting seeds using color sorters ensures compliance with export and import regulations, meeting quality standards set by different countries or regions.

Overall, the application of seed color sorters is pivotal in ensuring the production of high-quality seeds, maintaining consistency, meeting market demands, and contributing to the efficiency and success of agricultural and food processing industries.

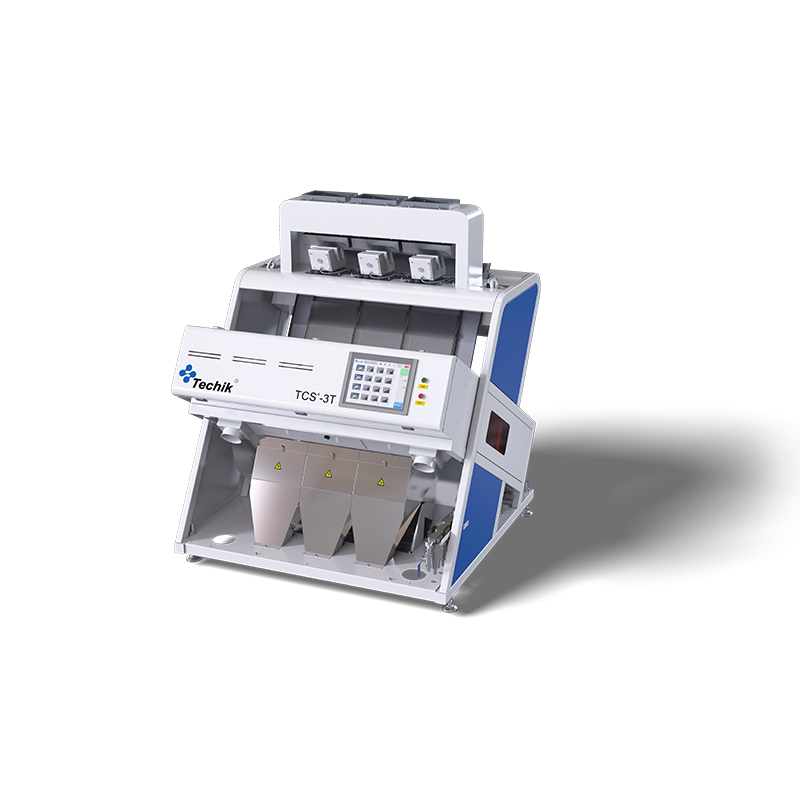

Techik Vegetable Tomato Sesame Seed Grading and Sorter Separator Machines are sophisticated machines equipped with various features designed to effectively sort seeds based on their color and other characteristics. Some key features of Techik Vegetable Tomato Sesame Seed Grading and Sorter Separator Machines include:

High-Resolution Cameras: These sorters are equipped with high-quality cameras that capture detailed images of the seeds as they pass through the sorting mechanism. These cameras provide precise and clear images for accurate color detection.

Advanced Optical Sensors: Utilizing advanced sensor technology, these sorters can detect subtle color differences and other characteristics such as size, shape, and defects in seeds.

Customizable Sorting Parameters: Seed color sorters offer customizable settings to adjust sorting parameters such as color thresholds, shape recognition, size sorting, and defect detection. This flexibility allows customization based on specific seed varieties and quality requirements.

Real-Time Image Processing: The machines use real-time image processing algorithms to analyze the captured images of seeds swiftly. This enables rapid decision-making for sorting based on predefined criteria.

High Sorting Accuracy: With the aid of sophisticated algorithms and precise sensors, seed color sorters achieve high sorting accuracy, minimizing false positives and ensuring only the targeted seeds are sorted.

Multiple Sorting Modes: These sorters often have multiple sorting modes to accommodate various requirements. They can sort based on color, size, shape, and even specific defects or foreign material.

High Throughput Capacity: Seed color sorters are designed for high throughput, capable of processing large quantities of seeds within a short period. This feature significantly increases efficiency in seed production.

User-Friendly Interface: Most seed color sorters come with user-friendly interfaces that allow operators to easily monitor the sorting process, adjust settings, and perform maintenance tasks conveniently.

These features collectively enable seed color sorters to efficiently and accurately sort seeds based on their color and other characteristics, ensuring high-quality seed output for various agricultural and food processing applications.