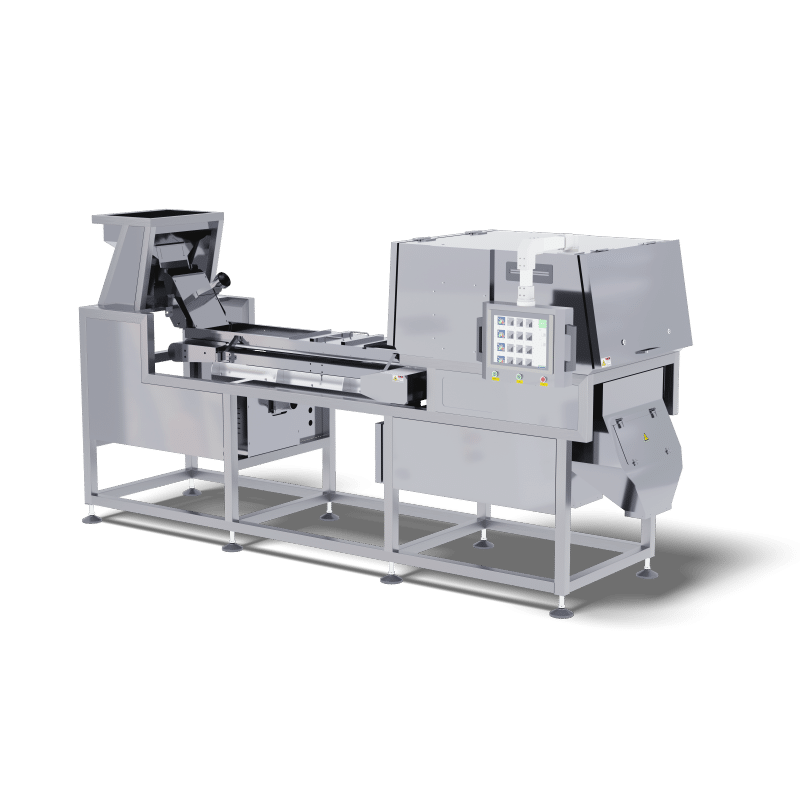

Raisin Dried Fruit Vegetable Optical Sorting Machine

Techik Raisin Dried Fruit Vegetable Optical Sorting Machine is a type of optical sorting machine that is specifically designed for sorting raisins based on their color and shape. Raisins are dried grapes, and their color can vary depending on factors such as grape variety, drying method, and storage conditions.

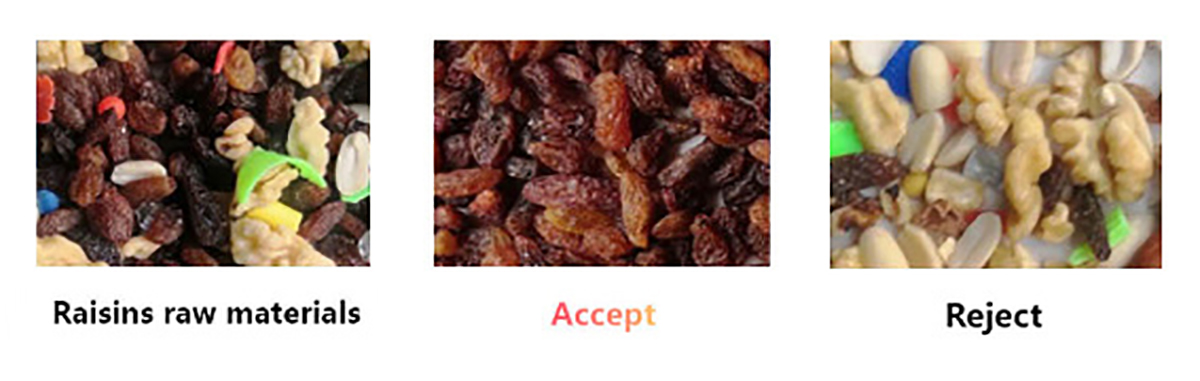

The sorting performance of Techik Raisin Dried Fruit Vegetable Optical Sorting Machines:

The principle of operation of Techik Raisin Dried Fruit Vegetable Optical Sorting Machine typically involves the following steps:

Feeding: Raisins are fed into the color sorter through a hopper or conveyor belt, and they are evenly distributed on the sorting belt or chute.

Optical Sensing: Optical sensors in the color sorter capture images of the raisins as they pass through the sorting area. These sensors are typically designed to detect specific color characteristics of raisins, such as their hue, intensity, and saturation.

Image Processing: The captured images are processed by the color sorter's software, which analyzes the color characteristics of each raisin in real-time. The software uses predefined criteria or user-set parameters to determine whether a raisin meets the desired color specifications or not.

Sorting: Based on the analysis of the color characteristics, the color sorter's software classifies each raisin as acceptable or unacceptable based on the predetermined criteria. Unacceptable raisins, which may be discolored, damaged, or have other impurities, are rejected and separated from the acceptable raisins.

Ejection: Once the raisins are classified, the color sorter uses various mechanisms, such as air jets, mechanical paddles, or conveyor belts, to selectively remove the rejected raisins from the main product stream and collect them in a separate container for further disposal or processing.

Collection: The sorted and acceptable raisins continue along the main product stream and are collected for further processing, packaging, or distribution.