Sorting is a vital step in many industries, including food processing, where quality and safety are paramount. In chili pepper processing, sorting helps remove defective peppers and foreign materials, ensuring only high-quality products reach the market. Let’s break down the general sorting process and examine how it applies to chili pepper production.

1. Feeding the Chili Peppers

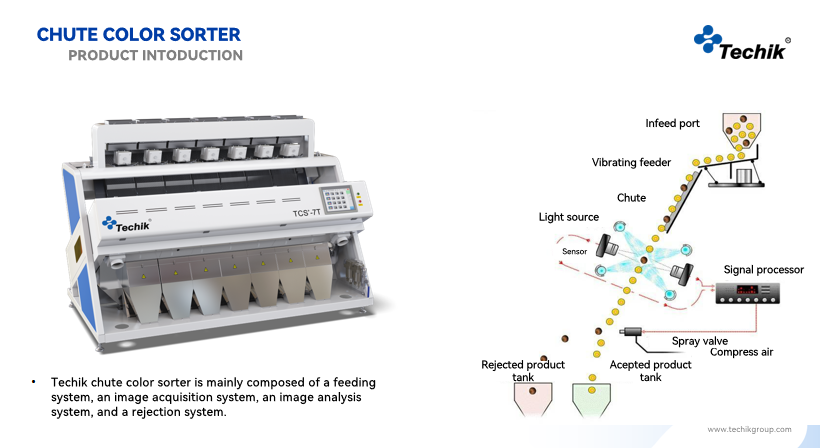

The process begins by feeding the chili peppers into the sorting machine via a conveyor belt or hopper. Chili peppers vary in size, shape, and color, which makes manual sorting inefficient. Automation ensures a continuous flow of peppers for inspection and separation.

2. Inspection and Detection

Once inside the sorting machine, advanced detection technologies come into play. For chili peppers, this includes:

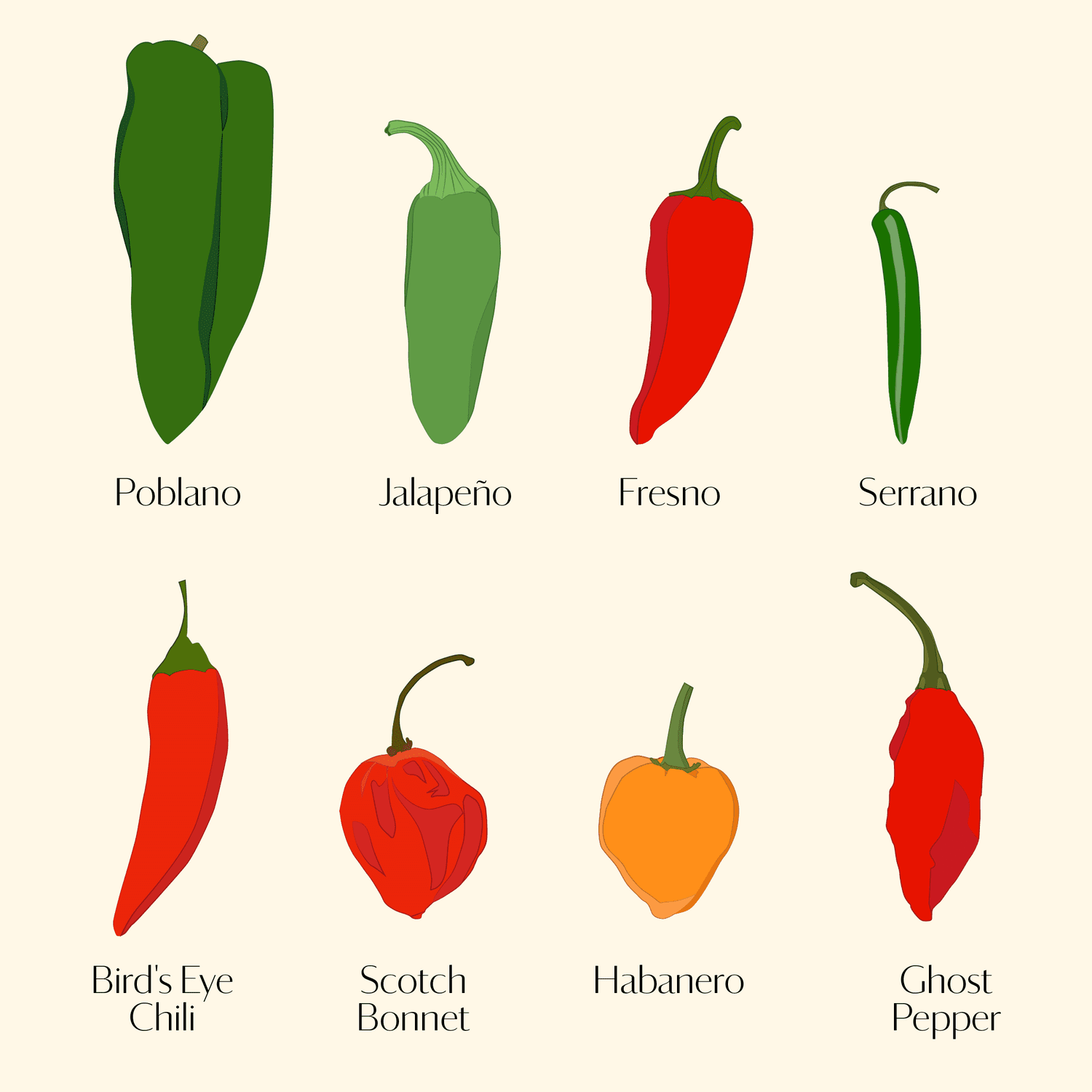

- Color Sorting: Techik’s color sorters use multi-spectrum technology to analyze the peppers’ color and detect defects. This helps differentiate between high-quality peppers and those that are under-ripe, overripe, or damaged.

- Size and Shape Detection: Sorting systems measure each chili pepper's size and shape, discarding those that do not meet the required standards.

- Impurity Detection: Chili peppers often carry impurities like stems, leaves, and plant debris, which need to be removed for a cleaner product.

3. Foreign Material Detection: X-Ray and Metal Detection

In addition to visual defects, foreign materials can also contaminate chili pepper batches. Techik’s X-Ray inspection systems identify objects like stones, stems, or other non-pepper materials. Metal detectors are also crucial for spotting any metallic contamination that may have entered the production line, ensuring food safety and compliance with industry regulations.

4. Classification and Sorting

After detection, the system classifies the peppers. Based on the quality data collected, defective or contaminated peppers are separated from the batch. Using air jets or mechanical arms, the defective peppers are directed into discard bins, while the high-quality ones continue for packaging.

5. Collection and Final Processing

Sorted chili peppers are collected and transferred for further processing, such as drying, grinding, or packaging. The sorting process ensures that only the best peppers make it to the market, improving overall product quality and customer satisfaction.

Techik’s Role in Enhancing Chili Pepper Sorting

Techik’s cutting-edge optical sorting machines combine visual detection with X-Ray and metal detection technologies. By integrating these methods, Techik ensures that chili pepper processors can remove impurities and foreign objects efficiently. This not only increases production speed but also guarantees food safety and quality. With Techik’s technology, chili pepper producers can confidently meet industry standards and customer expectations.

Post time: Sep-11-2024