A rice color sorter is a specialized machine used in the rice processing industry to sort and classify rice grains based on their color. Its primary function is to identify and remove defective or discolored grains from a batch of rice, ensuring that only high-quality grains are packaged and delivered to consumers.

Here’s how a rice color sorter typically works:

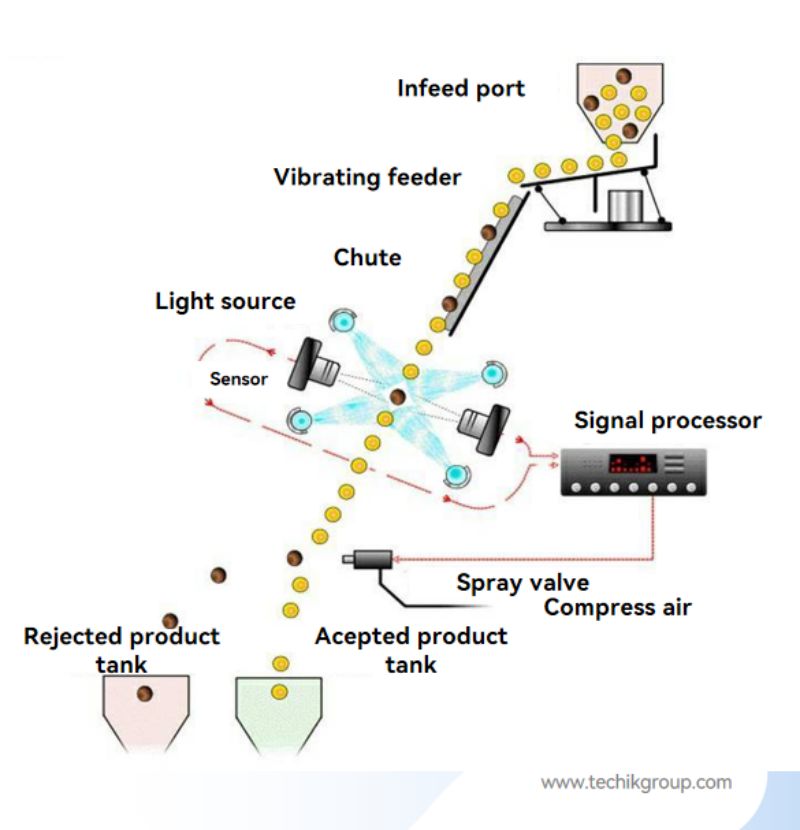

Input and Inspection: The rice grains are fed into the machine’s hopper, from where they are evenly spread onto a conveyor belt or chute for inspection.

Detection of Discoloration: As the rice moves along the conveyor belt or chute, it passes through a series of sensors, cameras, or optical systems that analyze each grain’s color and characteristics.

Sorting Process: The machine’s software and hardware components identify grains that deviate from the acceptable color range or have defects such as discoloration, spots, or impurities. Upon detection, these flawed grains are separated from the good ones.

Ejection of Defective Grains: Defective grains are removed by a system of air jets or mechanical arms that precisely target and redirect the unwanted grains away from the main flow of rice.

Collection of Sorted Rice: After the sorting process, the high-quality, properly colored rice grains continue along the conveyor belt or chute for collection in designated containers.

The rice color sorter uses advanced technology such as cameras, sensors, and image processing software to swiftly and accurately identify and remove defective grains. This process not only ensures a higher quality of rice for consumers but also reduces wastage and enhances the overall efficiency of rice production.

By removing discolored or imperfect grains, the color sorter helps maintain consistent quality and appearance, meeting the stringent standards set by consumers and the market for premium-grade rice products.

Take Basmati rice as an example. Sorting machines, including color sorters, play a vital role in the processing of Basmati rice, a long-grain aromatic rice known for its unique fragrance and delicate taste. Basmati rice sorting involves similar processes as mentioned earlier but is particularly crucial due to the premium quality expected from Basmati grains.

Quality Control for Basmati Rice: Basmati rice is highly valued for its distinct appearance, long slender grains, and pristine white color. Any discoloration, broken grains, or impurities can significantly impact its quality and market value.

Sorting for Color and Impurities: In the case of Basmati rice sorting, the color sorter uses its optical systems or sensors to meticulously examine each grain for color variations, defects, and impurities. Basmati rice often undergoes sorting to remove discolored or imperfect grains that might affect its characteristic appearance and taste.

Precision Sorting: The sorting machine employs high-resolution cameras and advanced software algorithms to detect even minor deviations in color, shape, size, or defects. This level of precision ensures that only the highest quality Basmati grains meeting the specified standards are selected.

Rejecting Imperfections: When a defective or discolored grain is identified, the sorting machine swiftly separates it from the rest of the batch using air jets or mechanical arms, ensuring that only premium-quality Basmati rice proceeds for packaging.

Preserving Premium Quality: By employing this sorting process, Basmati rice producers maintain the premium quality and uniform appearance of the rice, meeting the stringent requirements and expectations of consumers and markets worldwide.

The use of color sorting machines in the Basmati rice industry not only helps to enhance the overall quality and marketability of the rice but also ensures consistency in appearance, meeting the high standards demanded by consumers globally for this premium variety of rice.

Post time: Dec-21-2023