In the world of industrial processing, the need for efficient, precise, and high-speed sorting is paramount. Color sorters have long been a staple in industries like agriculture, food processing, and manufacturing, but the advent of Artificial Intelligence (AI) has brought about a transformative shift in the capabilities of these color sorting machines. In this article, we’ll explore the key differences between traditional color sorters and AI-powered color sorters, focusing on their abilities to recognize shape, color, and detect defects.

Traditional color sorters have been instrumental in basic sorting tasks based on color for many years. They excel at efficiently segregating items with distinct color differences. Here’s a closer look at their capabilities:

Color Recognition: Traditional sorters are highly effective at color-based sorting. They can swiftly and accurately separate items based on noticeable color disparities.

Shape Recognition: While they can be configured for shape-based sorting, their capabilities are typically rudimentary, making them less suitable for intricate or complex shape recognition tasks.

Defect Detection: Traditional color sorters are usually limited in their ability to identify subtle defects or material irregularities. They lack advanced image processing and machine learning features, which means that subtle defects often go unnoticed.

Customization: Traditional sorters are less customizable. Adapting to new sorting criteria or changing requirements often involves substantial reengineering.

Learning and Adaptation: Traditional sorters do not have the capacity to learn or adapt to new conditions or requirements over time.

AI has revolutionized color sorting by introducing advanced image processing, machine learning, and customization capabilities. AI-powered sorters provide a substantial upgrade in the following ways:

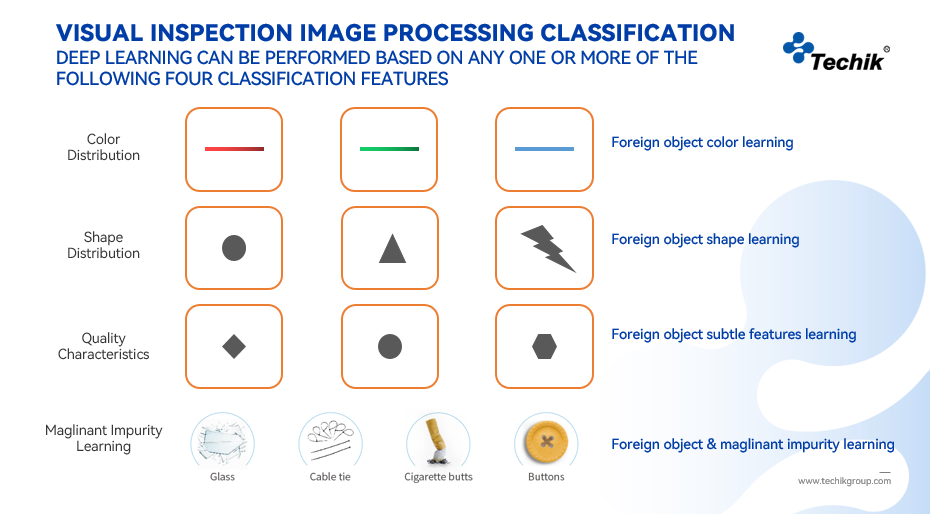

Color Recognition: AI enhances color recognition, making it suitable for complex color patterns and subtle color variations.

Shape Recognition: AI can be trained to recognize intricate shapes or patterns, allowing for precise shape-based sorting. This feature is invaluable in industries that require complex shape recognition.

Defect Detection: AI-powered systems excel at identifying subtle defects or irregularities in materials. Advanced image processing and machine learning capabilities ensure that even the most minor defects are detected, making them ideal for quality control applications.

Customization: AI-powered sorters are highly customizable, easily adapting to new sorting criteria and evolving requirements without the need for significant reengineering.

Learning and Adaptation: AI systems have the ability to learn and adapt to new conditions and requirements over time, continuously improving their sorting accuracy.

In conclusion, while traditional color sorters are effective for basic color-based sorting, they fall short in tasks that require precise shape recognition and defect detection. AI color sorters offer advanced capabilities that significantly enhance performance in these areas, making them invaluable in industries where quality control and accurate sorting are paramount. The integration of AI has propelled color sorters into a new era of efficiency and precision, paving the way for a wide range of applications across diverse industries.

Techik can provide color sorters with AI in different sections such as nuts, seeds, cereals, grains, beans, rice and etc. With Techik AI-powered color sorters, it is reality for you to customize your sorting requirements. You identify your defects and impurities.

Post time: Oct-27-2023