Hair Feather Insect Corpse Visual Color Sorter

Scanty foreign elements like hair not only cause a surge in consumer grievances but also stand as an enduring challenge that has plagued food processing enterprises for quite some time.

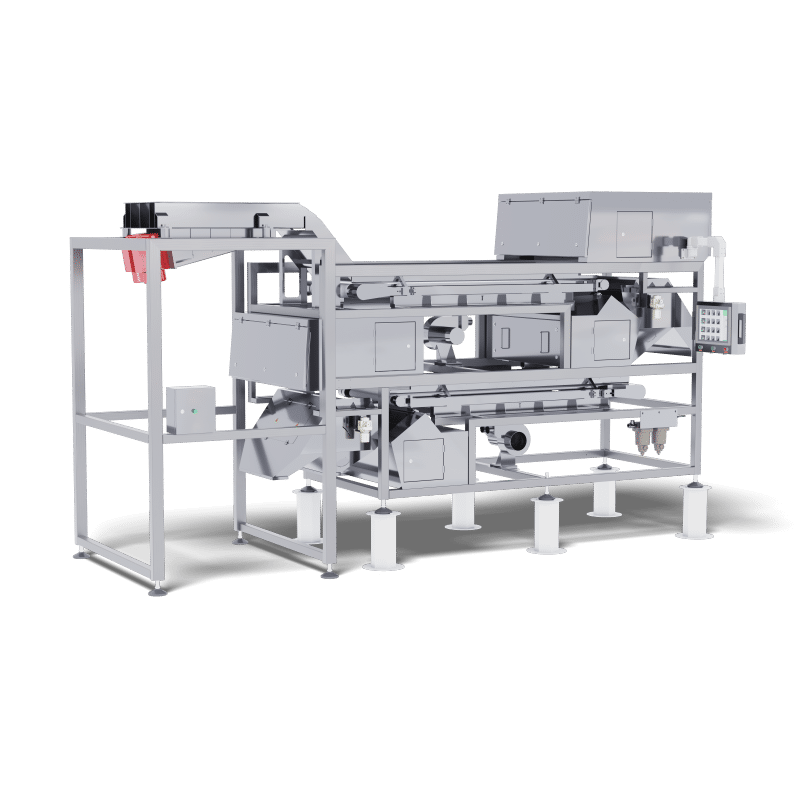

Techik Hair Feather Insect Corpse Visual Color Sorter possesses the capability to classify diverse commodities, including dehydrated shallots, dehydrated garlic, carrots, peanuts, tea leaves, peppers, and others. By harnessing the prowess of AI-driven color and shape sorting, it effectively replaces the tedious task of manually scrutinizing trivial foreign intrusions like hair, feathers, strings, and insect remains. With an impressive sorting rate, elevated output, and minimal loss of raw materials, this innovative sorter paves the way for superior productivity.

Moreover, Techik Hair Feather Insect Corpse Visual Color Sorter, fortified with IP65 protection level and an impeccable hygienic design, proves its versatility in intricate and ever-changing processing settings. Its applicability spans a wide array of sorting scenarios, encompassing the classification of fresh, frozen, and freeze-dried fruit and vegetable products, as well as during the stages of food processing, frying, and baking.

The sorting performance of Techik Hair Feather Insect Corpse Visual Color Sorter:

The application of a Hair Feather Insect Corpse Visual Color Sorter is in the food processing industry. It is used to detect and remove unwanted foreign matter such as hair, feathers, strings, and insect corpses from food products during the sorting process.

The sorter employs advanced visual color recognition technology and artificial intelligence to identify and categorize these minor foreign objects based on their color and shape. By doing so, it ensures that the final food products are free from such contaminants, meeting high-quality standards and complying with food safety regulations.

This type of color sorter is particularly useful in sorting products like fruits, vegetables, nuts, grains, and other food items where the presence of hair, feathers, or insect remains could lead to consumer complaints and affect the overall product quality. By automating this sorting process, the sorter improves efficiency, reduces manual labor, and minimizes the risk of human error, thereby increasing the productivity of food processing companies and ensuring a safer and cleaner end product for consumers.