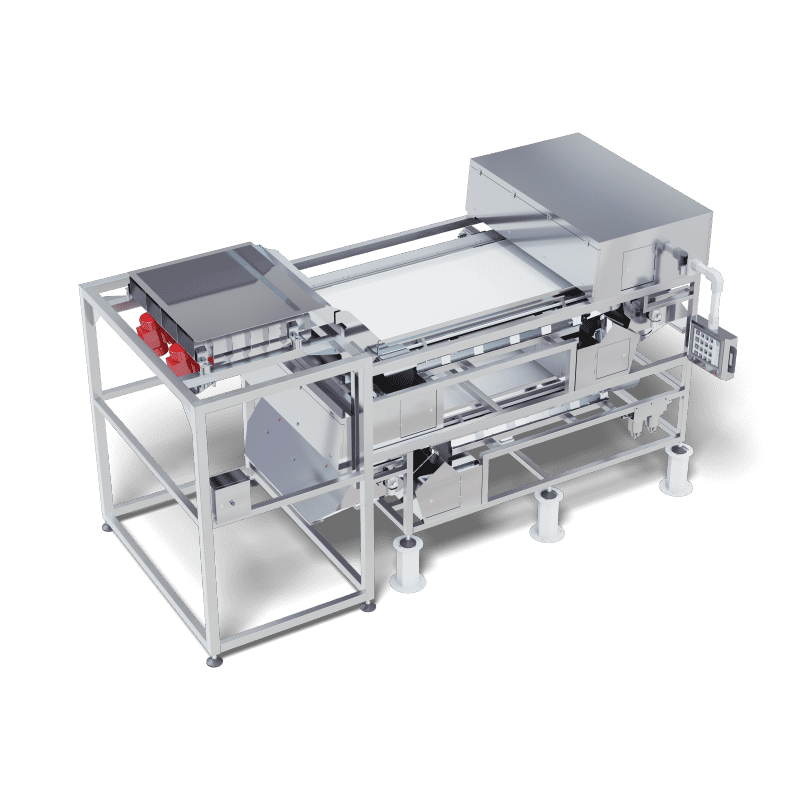

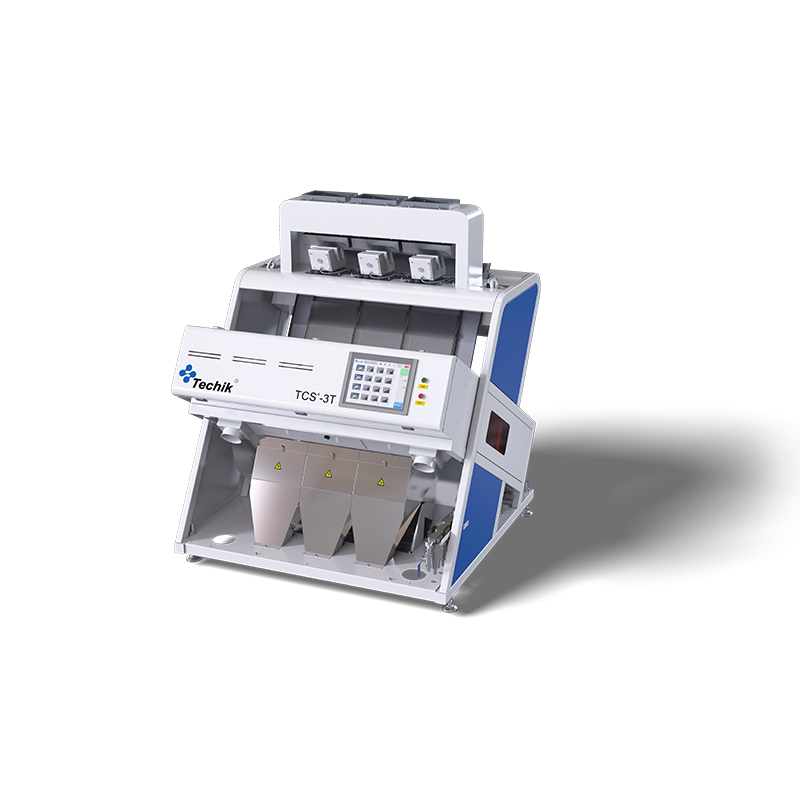

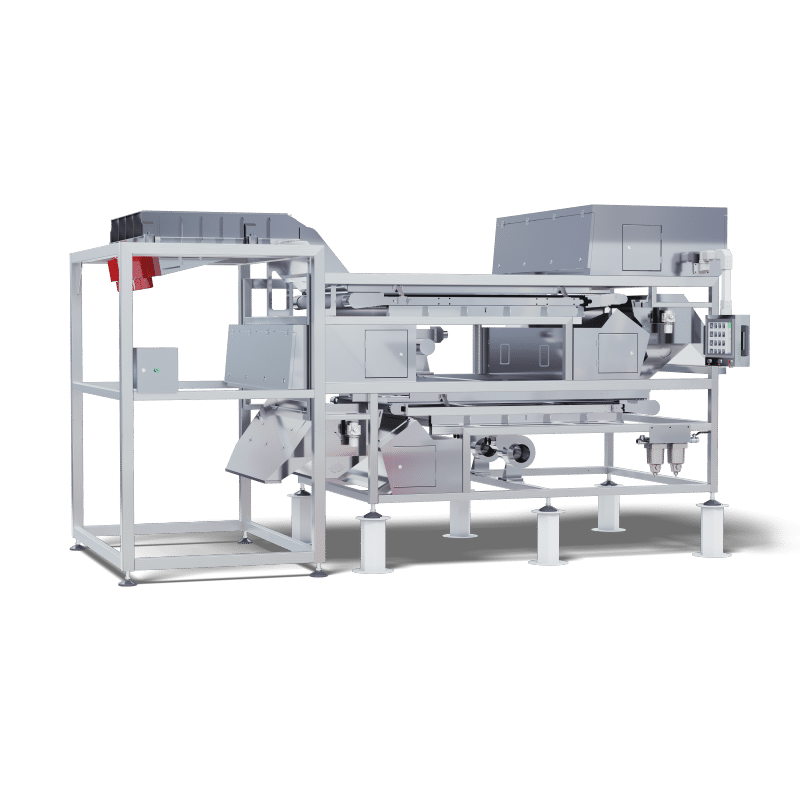

Frozen and Dehydrated Vegetable Color Sorter

In the realm of food processing, the meticulous sorting and quality control of frozen and dehydrated vegetables have become paramount for maintaining high standards of visual appeal, taste, and marketability. Color sorter machines have emerged as indispensable tools within this industry, offering an array of features, advantages, and versatile applications that ensure superior product quality and consumer satisfaction.

The sorting performance of Techik Frozen and Dehydrated Vegetable Color Sorter:

Techik Frozen and Dehydrated Vegetable Color Sorter can sort frozen and dehydrated vegetable based on various color characteristics, including:

Frozen Vegetable Processing Plants: Ensures only top-quality vegetables enter the freezing process, maintaining product integrity.

Dehydrated Vegetable Production: Selects uniform and visually appealing vegetables for dehydration, crucial for final product quality.

Ready-to-Eat and Convenience Foods: Provides consistently high-quality, visually appealing vegetables for pre-cut and packaged convenience food products.

Canning and Preservation: Assures the quality of vegetables preserved through canning or other preservation methods.

Export and Domestic Markets: Ensures that vegetables meet the aesthetic expectations of both domestic and international consumers, enhancing market competitiveness.

Frozen and dehydrated vegetable color sorters boast advanced technological features tailored for precision sorting. These machines utilize high-resolution cameras, intelligent algorithms, and cutting-edge optical sensors to detect and segregate vegetables based on color, size, shape, and defects. Adjustable parameters allow for precise customization, accommodating various vegetable types and quality requirements.

Advantages:

The utilization of color sorters in processing frozen and dehydrated vegetables presents numerous advantages. These include:

Enhanced Quality Control: Ensures uniformity in appearance, eliminating discolored or defective pieces and maintaining consistent product quality.

Increased Efficiency: Streamlines the sorting process, reducing manual labor and enhancing overall production efficiency.

Waste Reduction: Minimizes wastage by accurately segregating imperfect vegetables, thereby optimizing yield and profitability.

Compliance with Standards: Helps meet stringent quality standards and regulatory requirements for food safety and consumer satisfaction.